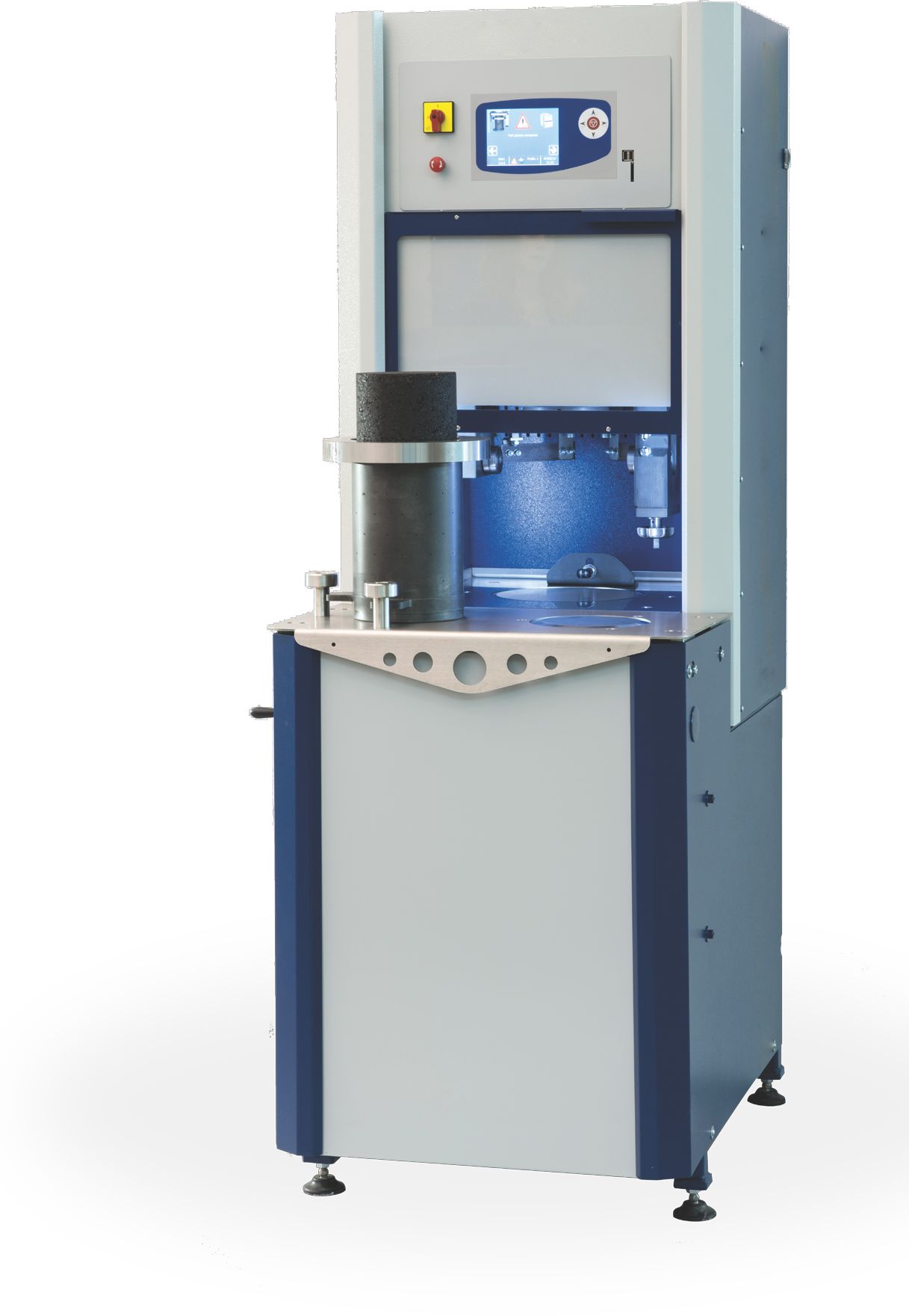

Description

ASTM D6925 • EN 12697-10 • EN 12697-31 • AASHTO T312

- Used to simulate and reproduce the real compaction conditions under actual road paving operations, hence determining the compaction properties of the asphalt.

- Such compaction is achieved in a fully automatic way, by combining the rotary action and the vertical resultant force applied by a Mekanik head. The Compactor comprises a highly rigid steel Gövde ensuring excellent angle control.

- Load is applied by an electro-pneumatic cylinder, servo-controlled by a precision pressure regulator; the height is measured by a linear transducer. Gyratory motion is generated by an eccentric high precision system allowing an easy set up with precision and constant angle of gyration.

- The rotation speed is controlled by an inverter through on board computer control.

- Using the proper perforated mould, the Compactor is able to run tests also on cold emulsified asphalt mix.

- The acquired results are also employed in the investigation of volumetric and Mekanik characteristics of the asphalt mix.

- The touch-screen icon interface allows an easy set up of the parameters and an immediate automatic execution of the test, data acquisition andprocessing,

graphics and file. A remote test control is available trough a dedicated software, provided in bundle.

AVAILABLE MODELS

| Kod | A-825/ASTM | A-825/EN |

|---|---|---|

| Standarts | ASTM | EN |

| Testıng Angle | 1.16° | 0.82° |

ACCESSORIES REQUIRED TO PERFORM THE TEST

| KodPack of 2 | A-825/ACC/100 | A-825 /ACC/150 |

|---|---|---|

| Mould | Ø 100 mm | Ø 150 mm |

| Base Plate | ● | ● |

| Mould with Holes For Cold Mixes | Ø 100 mm | Ø 150 mm |

| Top Penetration Piston | Ø 100 mm | Ø 150 mm |

| Metallic Disc | Pack of 2 | Pack of 2 |

| Filter Paper | Pack of 100 | Pack of 100 |